PALF PLANET Project

[PALF:Pineapple Leaf Fiber]

From Waste to Worth — Weaving Sustainability for People and Planet

PALF Planet Project

key statistics

Partners with 55 hectares of contracted farmland

Recycling 150 metric tons of pineapple leaves so far

Reduced 75 tons of CO₂ compared to cotton

creating a circular economy ecosystem for pineapples

STUF United Fund and UKL, a partnership for environmental sustainability

As a member of the United Nations Global Compact, holding consultative status with the UN Economic and Social Council (ECOSOC) and observer roles with the UNFCCC and UNEP, STUF United Fund (STUF) advances integrated models that link economic development with environmental stewardship. In alignment with the UN Sustainable Development Goals (SDGs), STUF encourages the private sector to transform its commitments into concrete actions that drive environmental sustainability.

STUF partners with textile innovator UKL on “PALF Planet Project ” (PALF: Pineapple Leaf Fiber), transforming agricultural waste into eco-friendly fibers and creating a model where farmers, businesses, and the planet thrive together. This initiative showcases how sustainability, circular economy, and climate action can be both practical and profitable.

Founded in 1988, UKL is a Certified B Corporation advancing sustainable fashion in line with the UN SDGs. Through innovations like PALF, which turns agricultural waste into low-carbon textiles, UKL promotes responsible production, climate action, and circular economy practices for a more sustainable apparel industry.

From Waste to Worth: Weaving Sustainability for People and Planet

Every year, more than 30 million metric tons of pineapples are grown across Asia, Central America, and other tropical regions. After harvesting the fruit, a surprising amount of leaves and stems are left behind. In fact, the leftover plant material is more than 1.4 times the weight of the fruit itself.

These leaves are often burned, which releases smoke and harmful particles into the air. Others are buried, which can use chemicals and takes months to break down. This process is expensive for farmers and harmful to the environment.

PALF

PALF (Pineapple Leaf Fiber) turns leftover pineapple leaves into valuable, sustainable materials.

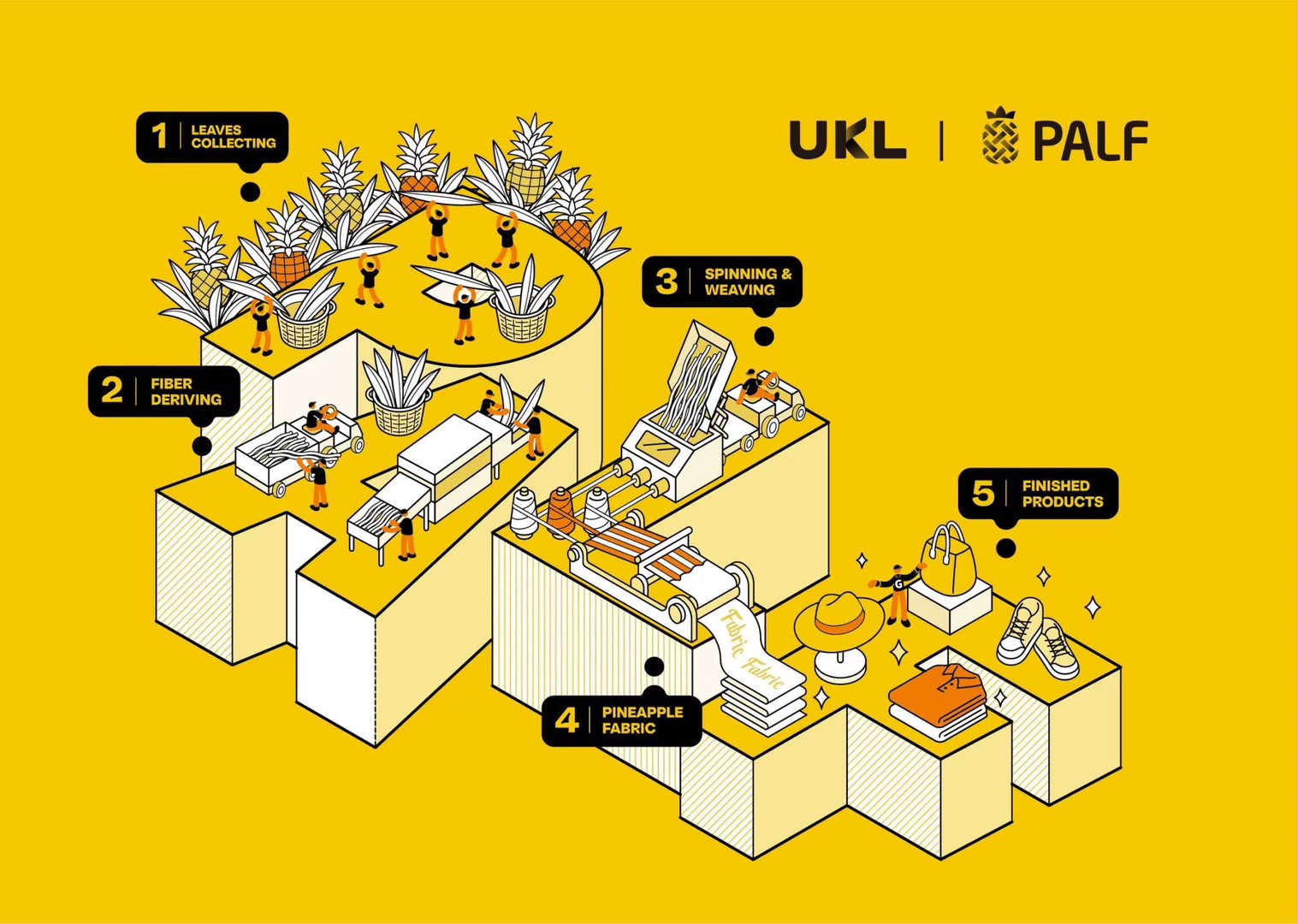

The process includes four key stages

PLANTATION where farmers collect leaves

EXTRACTION pineapple leaves extract include two parts: Fiber and Pulp

SPINNING fibers into yarn

FINAL PRODUCT creations such as clothing, bags, shoes, home goods and more

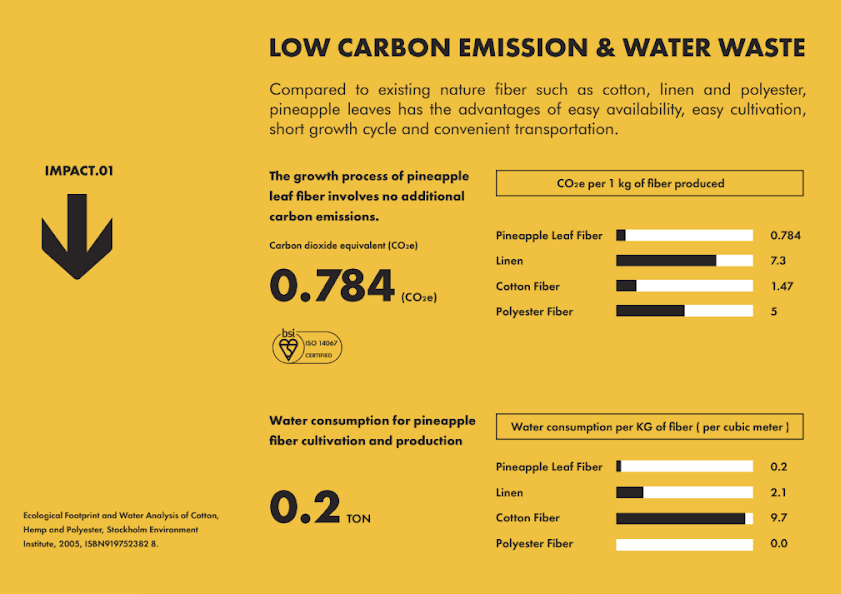

Project PALF transforms pineapple leaf waste into antibacterial, breathable, low carbon materials that support farming income, reduce environmental pollution, and create business value. With only 0.784 kilograms of carbon dioxide equivalent per kilogram, its carbon footprint is ten times lower than linen and half the impact of cotton. In addition, it creates less water waste compared to other materials.

STUF United Fund (STUF) continues to foster multi-stakeholder partnerships—including NGOs, corporations, governments, and UN agencies—to advance environmental sustainability and collective action toward the UN Sustainable Development Goals. Each sector contributes distinct capacities that are indispensable to an effective response to today’s urgent global challenges.